About Us

Colloidal silver is dissolved silver in water. Particles large enough to settle to the bottom of the container are filtered out. You get a clear, slightly yellow liquid with a mildly metallic taste. The stated shelf-life is 2 years, but it can last almost indefinitely with proper storage. It is not patentable, I do not use any mysterious proprietary processes. Standard accepted definitions are always used to describe colloid, ion and any scientific terms used on this website.

- Brian Humphreys

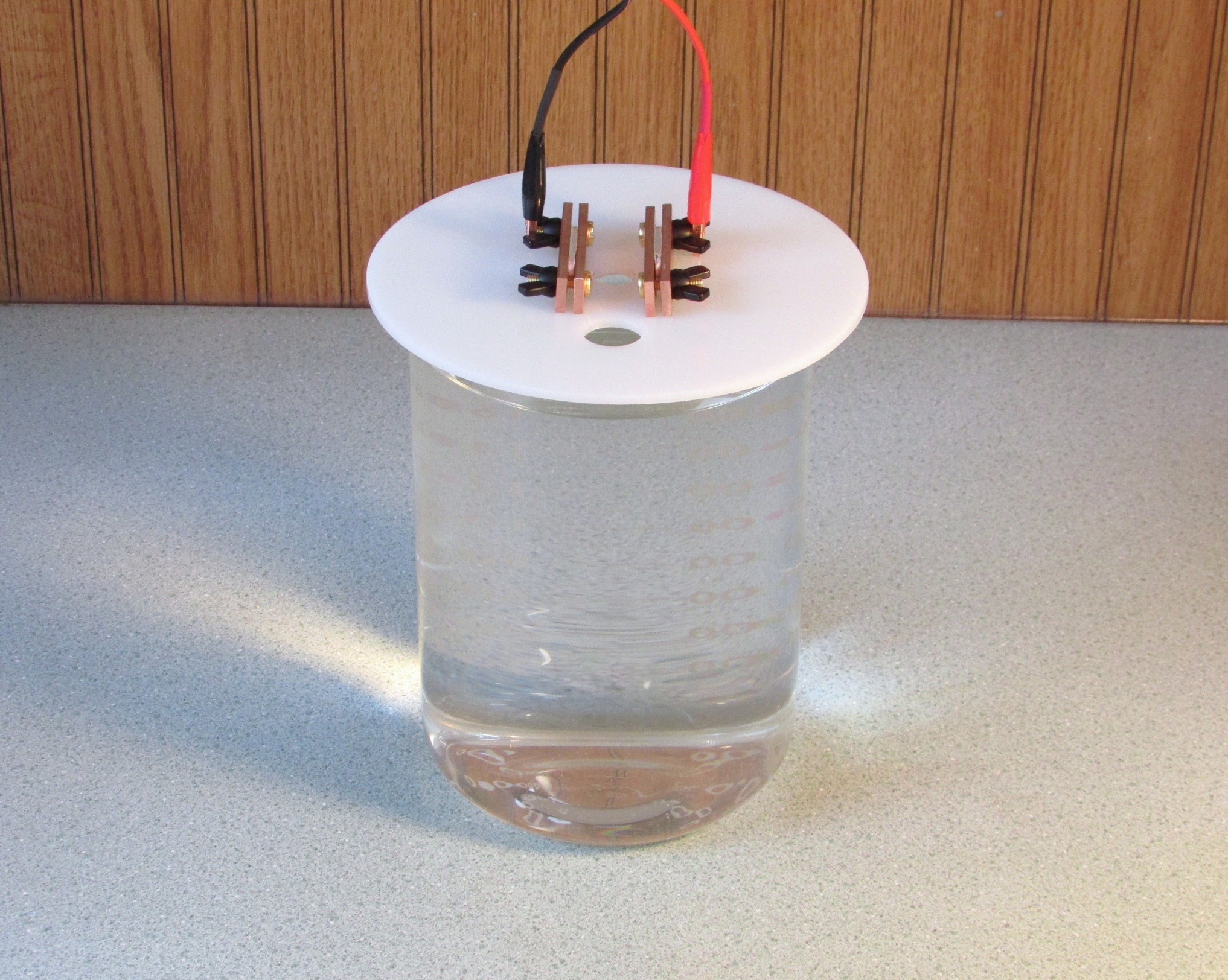

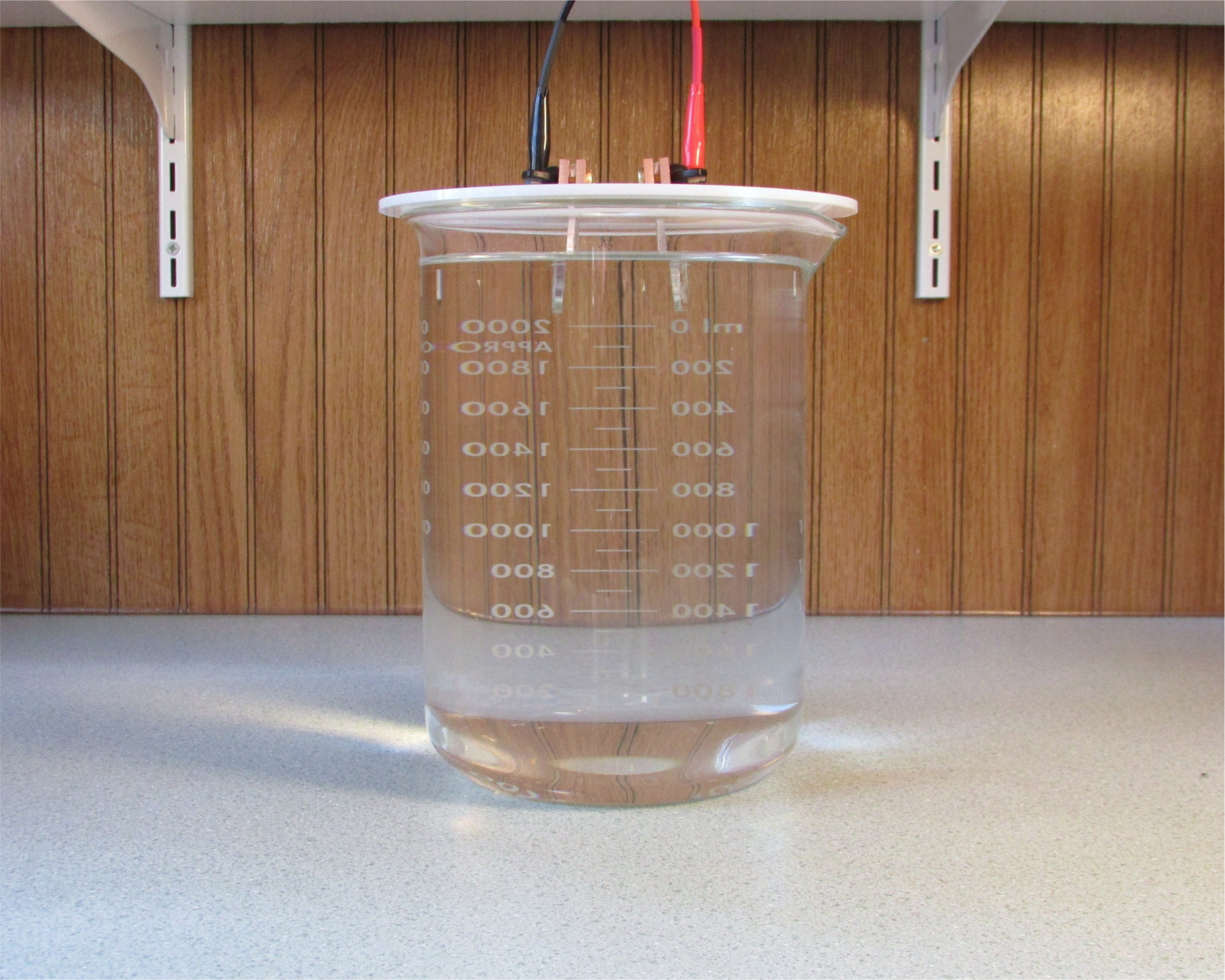

Silver in a Bottle is made with an electrolytic process which continually monitors the strength of the product. When the time is up, the energy input and strength are checked, before decanting the product with a filter; after which it is ready to bottle.

All ingredients are American made. Silver in a Bottle is made with silver which comes from a fully licensed supplier, is mined, refined and minted in America and has a purity of 99.9%. I have greater confidence in raw materials which meet our domestic standards than I have in imports. There are no secret or hidden ingredients because colloidal silver has no other ingredients; just pure silver and steam-distilled water.